A new eco-friendly packaging material made of straw and bioplastic

All claims expressed in this article are solely those of the authors and do not necessarily represent those of their affiliated organizations, or those of the publisher, the editors and the reviewers. Any product that may be evaluated in this article or claim that may be made by its manufacturer is not guaranteed or endorsed by the publisher.

Authors

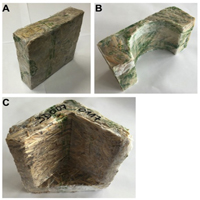

Packaging waste is cause for serious concern. Each year hundreds of millions of tons of packaging are produced, therefore solutions that drastically reduce their environmental impact are urgently needed. While the recycling of metal, wood, paper and cardboard packaging has been significantly improved, an efficient recycling or disposal of some plastics is not yet feasible. The European Union implemented various regulations concerning packaging and packaging waste and set some relevant short to medium-term targets for recycling and disposal rates. Over the last decade, the global trend of the eco-sustainable packaging market is heading in the same direction. The aim of this research is to develop an innovative and sustainable composite material for the production of tertiary packaging based on the combination of natural fibres and biodegradable biopolymers. In particular, the experimental application entailed the creation of prototypes consisting of a material made of straw and biodegradable plastic Mater-Bi© which is named NeoPalea. The new material was prototyped to verify its physical characteristics and to determine its potential use to replace current not-biodegradable packaging. The results show a good match with the characteristics of current polymers, suggesting that this material can be used as a potential substitute in packaging applications.

How to Cite

This work is licensed under a Creative Commons Attribution-NonCommercial 4.0 International License.