Structural design and experimental tests on a model of tensegrity greenhouse prototype

All claims expressed in this article are solely those of the authors and do not necessarily represent those of their affiliated organizations, or those of the publisher, the editors and the reviewers. Any product that may be evaluated in this article or claim that may be made by its manufacturer is not guaranteed or endorsed by the publisher.

Authors

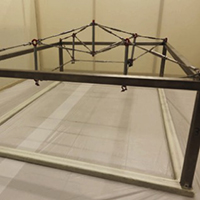

The aim of this paper is the analysis, proposal and application of a structural tensegrity configuration for greenhouses supporting structures suitable for lightweight covering, based on principles of design coherence, material savings and building durability. By means of the FEM software, Sofistik®, a tensegral greenhouse prototype was modelled and designed in accordance with EN 13031-1:2019. In order to calibrate the results of the FEM analysis, experimental load tests and displacement measurements made with a tensegrity reduced scale model on a tensegrity reduced scale model, created at the Department laboratory of the University of Bari, were compared with the results of the calculation analysis. The displacements of the prototype selected nodes were detected by Target tracking Technology in two load configurations and a control transducer was positioned on the central structural node. The comparison among the displacements of the detected nodes with those resulting from the FEM software calculations, for two different load configurations, show average percentage errors of 7.1% and 12.55%. The results of the T test for the different load configuration point out that the two series of values experimentally detected and calculated by the software are not significantly different. Finally, results in terms of the structural steel weight and maximum stress of the tensegral structure were compared with those of commercial structures, both with vaulted roof and duopitched roof, of single span greenhouses having the same covered ground area of the greenhouse prototype. The proposed tensegrity greenhouse prototype showed a 9.6% and 35.2% reduction of the structural steel weight compared to the vaulted roof and to the duo-pitched roof greenhouse respectively.

How to Cite

This work is licensed under a Creative Commons Attribution-NonCommercial 4.0 International License.