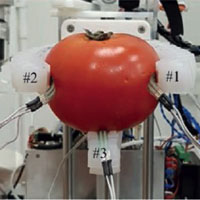

The design of a force feedback soft gripper for tomato harvesting

Published: 18 March 2021

Abstract Views: 4403

PDF: 1605

HTML: 683

HTML: 683

Publisher's note

All claims expressed in this article are solely those of the authors and do not necessarily represent those of their affiliated organizations, or those of the publisher, the editors and the reviewers. Any product that may be evaluated in this article or claim that may be made by its manufacturer is not guaranteed or endorsed by the publisher.

All claims expressed in this article are solely those of the authors and do not necessarily represent those of their affiliated organizations, or those of the publisher, the editors and the reviewers. Any product that may be evaluated in this article or claim that may be made by its manufacturer is not guaranteed or endorsed by the publisher.

Similar Articles

- Tiziana Bisantino, Vincenzo Pizzo, Maurizio Polemio, Francesco Gentile, Analysis of the flooding event of October 22-23, 2005 in a small basin in the province of Bari (Southern Italy) , Journal of Agricultural Engineering: Vol. 47 No. 4 (2016)

- Salvatore Faugno, Stefania Pindozzi, Roberta Infascelli, Collins Okello, Maria Nicolina Ripa, Lorenzo Boccia, Assessment of nitrogen content in buffalo manure and land application costs , Journal of Agricultural Engineering: Vol. 43 No. 2 (2012)

- Lelia Murgia, Giuseppe Todde, Maria Caria, Antonio Pazzona, A partial life cycle assessment approach to evaluate the energy intensity and related greenhouse gas emission in dairy farms , Journal of Agricultural Engineering: Vol. 44 No. s2 (2013): Proceedings of the 10th Conference of the Italian Society of Agricultural Engineering

- Terenziano Raparelli, Alexandre Ivanov, Giuseppe Pepe, Gabriella Eula, Analysis of the energy consumption of a rotary harrow , Journal of Agricultural Engineering: Vol. 52 No. 2 (2021)

- Md Nafiul Islam, Md Zafar Iqbal, Mohammod Ali, Milon Chowdhury, Shafik Kiraga, Md Shaha Nur Kabir, Dae-Hyun Lee, Jea-Keun Woo, Sun-Ok Chung, Theoretical transmission analysis to optimise gearbox for a 2.6 kW automatic pepper transplanter , Journal of Agricultural Engineering: Vol. 53 No. 4 (2022)

- Emanuel Rigon, Johnny Moretto, Riccardo Rainato, Mario Aristide Lenzi, Andrea Zorzi, Evaluation of the morphological quality index in the Cordevole river (Bl, Italy) , Journal of Agricultural Engineering: Vol. 44 No. 3 (2013)

- Andrea Formato, Giampiero Scaglione, Domenico Ianniello, Application of software for the optimization of the surface shape of nets for chestnut harvesting , Journal of Agricultural Engineering: Vol. 44 No. s2 (2013): Proceedings of the 10th Conference of the Italian Society of Agricultural Engineering

- Fabio Pezzi, Claudio Caprara, Francesco Bordini, TRANSMISSION OF IMPACTS DURING MECHANICAL GRAPE HARVESTING AND TRANSPORTATION , Journal of Agricultural Engineering: Vol. 39 No. 3 (2008)

- Fan Cui, Guoqi Dong, Baiping Chen, Penglin Yong, Suping Peng, Application of ground penetrating radar technology in moisture content detection of stored grain , Journal of Agricultural Engineering: Vol. 54 No. 1 (2023)

- Eliseo Roma, Pietro Catania, Mariangela Vallone, Santo Orlando, Unmanned aerial vehicle and proximal sensing of vegetation indices in olive tree (Olea europaea) , Journal of Agricultural Engineering: Vol. 54 No. 3 (2023)

<< < 10 11 12 13 14 15 16 17 18 19 > >>

You may also start an advanced similarity search for this article.

https://doi.org/10.4081/jae.2021.1090

https://doi.org/10.4081/jae.2021.1090