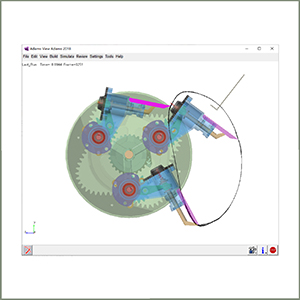

Optimal design of transplanting mechanism with differential internal engagement non-circular gear trains

Published: 9 September 2022

Abstract Views: 818

PDF: 427

Appendix: 96

HTML: 56

Appendix: 96

HTML: 56

Publisher's note

All claims expressed in this article are solely those of the authors and do not necessarily represent those of their affiliated organizations, or those of the publisher, the editors and the reviewers. Any product that may be evaluated in this article or claim that may be made by its manufacturer is not guaranteed or endorsed by the publisher.

All claims expressed in this article are solely those of the authors and do not necessarily represent those of their affiliated organizations, or those of the publisher, the editors and the reviewers. Any product that may be evaluated in this article or claim that may be made by its manufacturer is not guaranteed or endorsed by the publisher.

Similar Articles

- Alessio Cislaghi, Gian Battista Bischetti, Best practices in post-flood surveys: The study case of Pioverna torrent , Journal of Agricultural Engineering: Vol. 53 No. 2 (2022)

- Juan Ãngel Mintegui Aguirre, José Carlos Robredo Sánchez, Carlos de Gonzalo Aranoa, Pablo Huelin Rueda, Jorge Fallas, Felipe Cisneros, Pedro Cisneros, Adriana Urciuolo, Rodolfo Iturraspe, Forest use strategies in watershed management and restoration: application to three small mountain watersheds in Latin America , Journal of Agricultural Engineering: Vol. 45 No. 1 (2014)

- Salvatore Faugno, Luisa del Piano, Mariano Crimaldi, Gennaro Ricciardiello, Maura Sannino, Mechanical oil extraction of Nicotiana tabacum L. seeds: analysis of main extraction parameters on oil yield , Journal of Agricultural Engineering: Vol. 47 No. 3 (2016)

- Yane Ansanay, Praveen Kolar, Ratna Sharma-Shivappa, Jay Cheng, Sunkyu Park, Consuelo Arellano, Pre-treatment of biomasses using magnetised sulfonic acid catalysts , Journal of Agricultural Engineering: Vol. 48 No. 2 (2017)

- Ali Saeed, Alessandro Comegna, Giovanna Dragonetti, Nicola Lamaddalena, Angelo Sommella, Antonio Coppola, Soil electrical conductivity estimated by time domain reflectometry and electromagnetic induction sensors: Accounting for the different sensor observation volumes , Journal of Agricultural Engineering: Vol. 48 No. 4 (2017)

- Celeste Righi Ricco, Alberto Finzi, Viviana Guido, Elisabetta Riva, Omar Ferrari, Giorgio Provolo , Evaluation of ammonia emissions from filtration of digestate used for fertigation , Journal of Agricultural Engineering: Vol. 52 No. 3 (2021)

- Wioleta Radawiec, Janusz Gołaszewski, Barbara Kalisz, Solid tailings after supercritical CO2 extraction of lignocellulosic biomass as a source of quality biochar for energetic use and as soil improvement , Journal of Agricultural Engineering: Vol. 54 No. 3 (2023)

- Daniele Duca, Giovanni Riva, Ester Foppa Pedretti, Giuseppe Toscano, Chiara Mengarelli, Giorgio Rossini, Solid biofuels production from agricultural residues and processing by-products by means of torrefaction treatment: the case of sunflower chain , Journal of Agricultural Engineering: Vol. 45 No. 3 (2014)

- Simone Pascuzzi, Emanuele Cerruto, An innovative pneumatic electrostatic sprayer useful for tendone vineyards , Journal of Agricultural Engineering: Vol. 46 No. 3 (2015)

- Francesca Perazzolo, Gabriele Mattachini, Fulvia Tambone, Aldo Calcante, Giorgio Provolo, Nutrient losses from cattle co-digestate slurry during storage , Journal of Agricultural Engineering: Vol. 47 No. 2 (2016)

<< < 21 22 23 24 25 26 27 28 > >>

You may also start an advanced similarity search for this article.

https://doi.org/10.4081/jae.2022.1412

https://doi.org/10.4081/jae.2022.1412