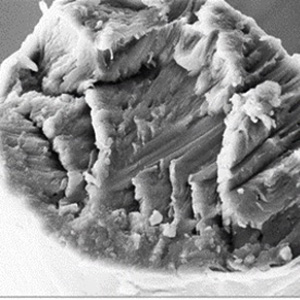

Reuse of livestock waste for the reinforcement of rammed-earth materials: investigation on mechanical performances

Published: 2 February 2023

Abstract Views: 1205

PDF: 265

HTML: 8

HTML: 8

Publisher's note

All claims expressed in this article are solely those of the authors and do not necessarily represent those of their affiliated organizations, or those of the publisher, the editors and the reviewers. Any product that may be evaluated in this article or claim that may be made by its manufacturer is not guaranteed or endorsed by the publisher.

All claims expressed in this article are solely those of the authors and do not necessarily represent those of their affiliated organizations, or those of the publisher, the editors and the reviewers. Any product that may be evaluated in this article or claim that may be made by its manufacturer is not guaranteed or endorsed by the publisher.

Similar Articles

- Monica Parlato, Simona M.C. Porto, Giovanni Cascone, Raw earth-based building materials: An investigation on mechanical properties of Floridia soil-based adobes , Journal of Agricultural Engineering: Vol. 52 No. 2 (2021)

- Maria Elena Menconi, Massimo Chiappini, Jan L.M. Hensen, David Grohmann, Thermal comfort optimisation of vernacular rural buildings: passive solutions to retrofit a typical farmhouse in central Italy , Journal of Agricultural Engineering: Vol. 48 No. 3 (2017)

- Daniele Torreggiani, Alberto Barbaresi, Francesca Dallacasa, Patrizia Tassinari, Effects of different architectural solutions on the thermal behaviour in an unconditioned rural building. The case of an Italian winery , Journal of Agricultural Engineering: Vol. 49 No. 1 (2018)

- Maria E. Menconi, David Grohmann, Piero Borghi, Dynamic thermal simulation on retrofitting scenarios for semi-extensive sheep farms , Journal of Agricultural Engineering: Vol. 45 No. 2 (2014)

- Francesco Barreca, Giuseppe Modica, Salvatore Di Fazio, Viviana Tirella, Raimondo Tripodi, Carmelo Riccardo Fichera, Improving building energy modelling by applying advanced 3D surveying techniques on agri-food facilities , Journal of Agricultural Engineering: Vol. 48 No. 4 (2017)

- Francesco da Borso, Alessandro Chiumenti, Marco Mezzadri, Francesco Teri, Noxious gases in rabbit housing systems: effects of cross and longitudinal ventilation , Journal of Agricultural Engineering: Vol. 47 No. 4 (2016)

- Alessandro D'Emilio, Simona M.C. Porto, Giovanni Cascone, Marco Bella, Marco Gulino, Mitigating heat stress of dairy cows bred in a free-stall barn by sprinkler systems coupled with forced ventilation , Journal of Agricultural Engineering: Vol. 48 No. 4 (2017)

- Salvatore Praticò, Raimondo Tripodi, Viviana Tirella, Salvatore Di Fazio, Francesco Barreca, Giuseppe Modica, Proposal of an integrated 3D architectural survey method for application in historic agri-food building analysis and representation , Journal of Agricultural Engineering: Vol. 54 No. 3 (2023)

- Marzia Quattrone, Giovanna Tomaselli, Lara Riguccio, Patrizia Russo, Assessment of the territorial suitability for the creation of the greenways networks: Methodological application in the Sicilian landscape context , Journal of Agricultural Engineering: Vol. 48 No. 4 (2017)

- Francesca Valenti, Simona M.C. Porto, Giovanni Cascone, Claudia Arcidiacono, Potential biogas production from agricultural by-products in Sicily. A case study of citrus pulp and olive pomace , Journal of Agricultural Engineering: Vol. 48 No. 4 (2017)

You may also start an advanced similarity search for this article.

https://doi.org/10.4081/jae.2023.1434

https://doi.org/10.4081/jae.2023.1434