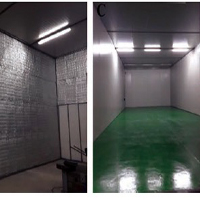

Environmental indoor thermal control of extra virgin olive oil storage room with phase change materials

Published: 27 November 2019

Abstract Views: 1342

PDF: 753

HTML: 262

HTML: 262

Publisher's note

All claims expressed in this article are solely those of the authors and do not necessarily represent those of their affiliated organizations, or those of the publisher, the editors and the reviewers. Any product that may be evaluated in this article or claim that may be made by its manufacturer is not guaranteed or endorsed by the publisher.

All claims expressed in this article are solely those of the authors and do not necessarily represent those of their affiliated organizations, or those of the publisher, the editors and the reviewers. Any product that may be evaluated in this article or claim that may be made by its manufacturer is not guaranteed or endorsed by the publisher.

Similar Articles

- Lelia Murgia, Giuseppe Todde, Maria Caria, Antonio Pazzona, A partial life cycle assessment approach to evaluate the energy intensity and related greenhouse gas emission in dairy farms , Journal of Agricultural Engineering: Vol. 44 No. s2 (2013): Proceedings of the 10th Conference of the Italian Society of Agricultural Engineering

- Roger Boulton, A self-sustainable winery, an advanced passive building and remote monitoring of environments in wineries , Journal of Agricultural Engineering: Vol. 48 No. s1 (2017): Special Issue

- Zhi He, Xinting Ding, Wei Hao, Kai Li, Weixin Gong, Zixu Li, Yongjie Cui, Calibration and experiments of discrete element flexible model parameters for kiwifruit stalk , Journal of Agricultural Engineering: Vol. 55 No. 4 (2024)

- Salvatore Faugno, Stefania Pindozzi, Collins Okello, Maura Sannino, Testing the application of an automatic milking system on buffalo (Bubalus bubalis) , Journal of Agricultural Engineering: Vol. 46 No. 1 (2015)

- Ye-jin Seo, Eunmi Hong, Jong-hyuk Lee, Young-joon Jeong, Byung-hun Seo, Soojin Jun, Seung-Jae Lee, Won Choi, Comparative study of coating agents for prevention of fine-dust-induced light transmittance reduction in greenhouse covering materials , Journal of Agricultural Engineering: Vol. 53 No. 2 (2022)

- Aristide Timene, Haman Djalo, Design of a five-bar duckbill-type mechanism for sorghum transplanting , Journal of Agricultural Engineering: Vol. 54 No. 2 (2023)

- Ali Saeed, Alessandro Comegna, Giovanna Dragonetti, Nicola Lamaddalena, Angelo Sommella, Antonio Coppola, Soil electrical conductivity estimated by time domain reflectometry and electromagnetic induction sensors: Accounting for the different sensor observation volumes , Journal of Agricultural Engineering: Vol. 48 No. 4 (2017)

- Alvaro Marucci, Danilo Monarca, Andrea Colantoni, Enio Campiglia, Andrea Cappuccini, Analysis of the internal shading in a photovoltaic greenhouse tunnel , Journal of Agricultural Engineering: Vol. 48 No. 3 (2017)

- Roberto Beghi, Simone V. Marai, Valentina Giovenzana, Enrico Ferrari, Riccardo Guidetti, Testing and design of a passive container for the optimisation of highbush blueberries (Vaccinium corymbosum L.) cold chain , Journal of Agricultural Engineering: Vol. 47 No. 2 (2016)

- Giacomo Scarascia-Mugnozza, Silvana Fuina, Sergio Castellano, Structural design and experimental tests on a model of tensegrity greenhouse prototype , Journal of Agricultural Engineering: Vol. 52 No. 3 (2021)

<< < 14 15 16 17 18 19 20 21 22 23 > >>

You may also start an advanced similarity search for this article.

https://doi.org/10.4081/jae.2019.947

https://doi.org/10.4081/jae.2019.947